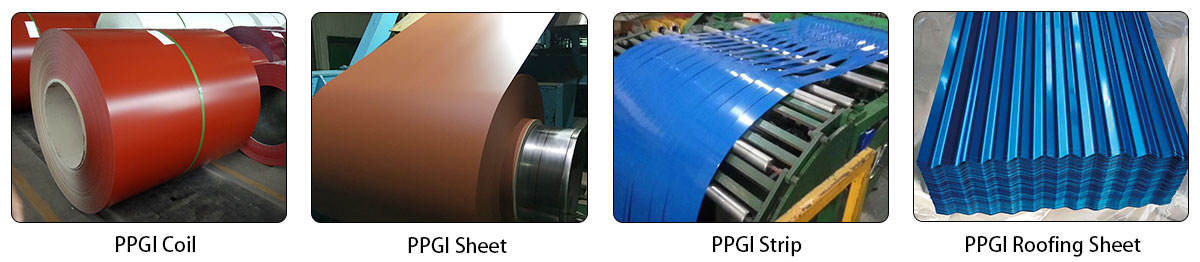

Color Coated Steel Coil

We support multiple delivery, if you have your own freight forwarder, you can also provide delivery to the designated address, through your own freight forwarder for shipping, we guarantee 100% delivery on time.

Talk to us today about your Requirements.

Item | Color Coated Steel Coil |

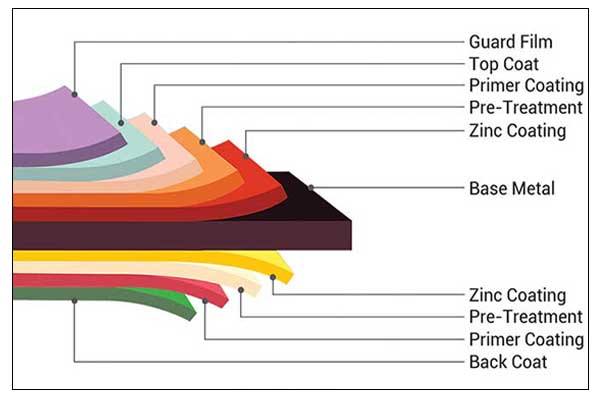

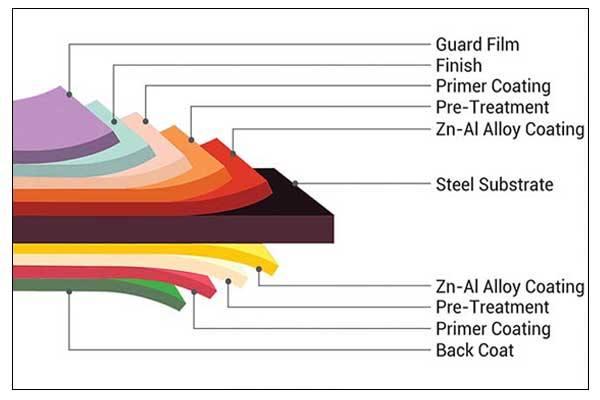

Substrate | GI, GL |

Thickness | 0.12 mm-1.2 mm |

Width | 600 mm-1250 mm |

Coil Weight | 3-5 tons (can be customized) |

Coatings | PE, SMP, HDP, PVDF |

Coating Thickness | Top: 11-35 μm Back: 5-14 μm |

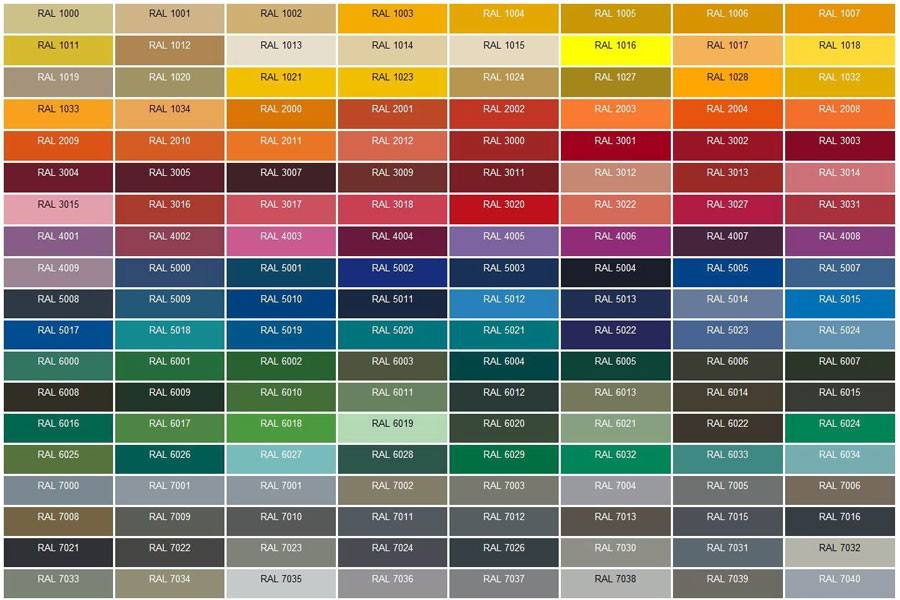

Colors | As per RAL Color (custom patterns are available) |

Package | Standard Export Package |

The colour coated coil rate starts from $500 to $1,300 per ton on the market. In fact, the color coated steel coil price is influenced by many factors, such as the substrate, thickness, color, coating, the thickness of the coating, printed pattern, etc. We suggest choosing the one that suits your needs and budget the best, rather than the price.

1. Substrates

According to the substrate, there are 3 kinds of color-coated steel coils to choose from, namely, cold-rolled steel (CR), galvanized steel (GI), and Al-Zn-coated steel (GL). Among them, CR is the cheapest one, but its corrosion resistance is not as good as that of GI or GL. Commonly, it is often used as interior lining panel, lamp, etc. While PPGL is expensive, but it is a great building material because of its great corrosion resistance and reflectivity. Below is a video for your reference.2. Coatings

The commonly-used top coatings include polyester (PE), silicone modified polyester (SMP), high durability polyester (HDP), and polyvinylidene fluoride (PVDF). PVDF is more expensive than others, while its physical properties are also much better. Also, it is suggested to choose the paint according to the different use environments.There are many factors to consider before purchase, such as the substrate, coating, thickness, cost, etc. Below are some tips for your reference.

1. Select the appropriate one for the uses and purposes

It will be very different for different uses. You need to take the corrosion of the use environment, expected service life, and durability into consideration. It matters how to choose the substrate, thickness, and coating. So inform us where and what you will use the color coated coil for, our professional sales team will offer suitable options.

2. Pay more attention to the product quality

There are many color-coated steel coils on the market. Some are very cheap. But you need to pay more attention to the quality rather than the price. If possible, you can ask for samples for reference or visit the factory on-site.