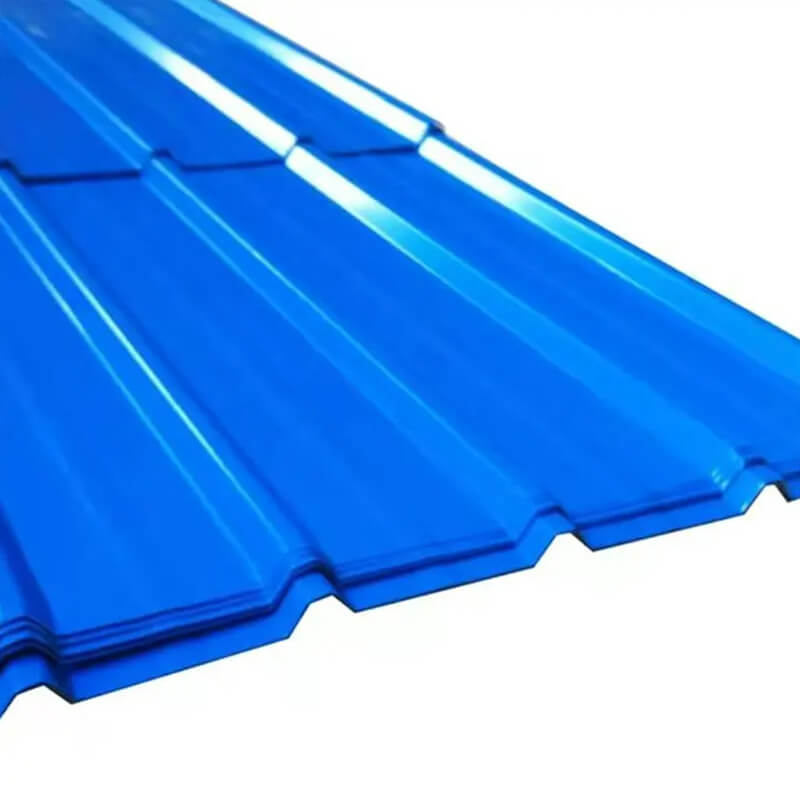

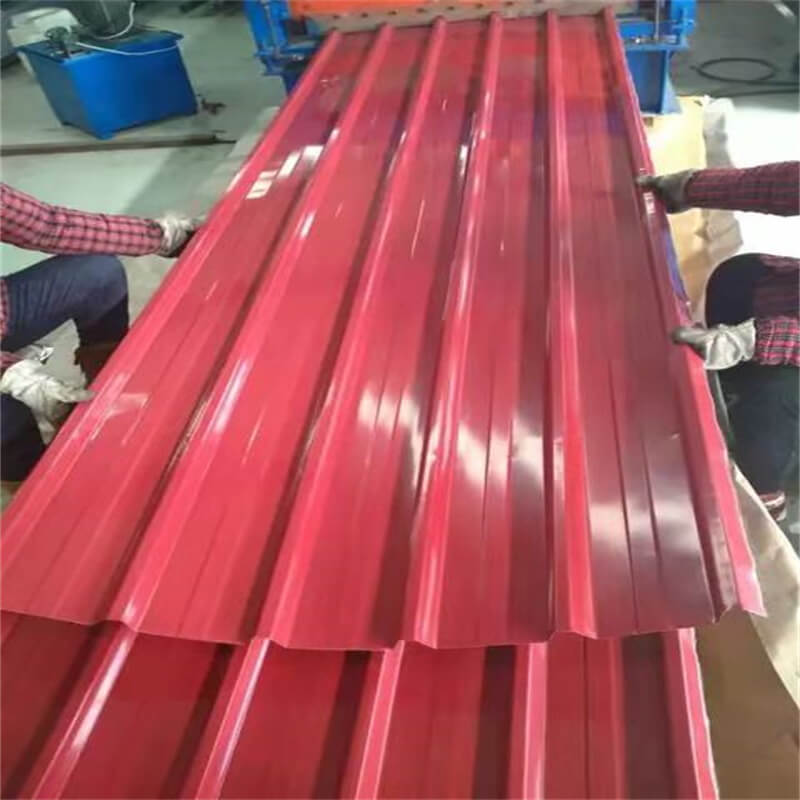

Color Corrugated Sheet

We support multiple delivery, if you have your own freight forwarder, you can also provide delivery to the designated address, through your own freight forwarder for shipping, we guarantee 100% delivery on time.

Talk to us today about your Requirements.

| Thickness | 0.12 mm-1.2 mm |

| Overall Width | 600 mm-1,250 mm |

| Effective Width | 750 mm-1,100 mm |

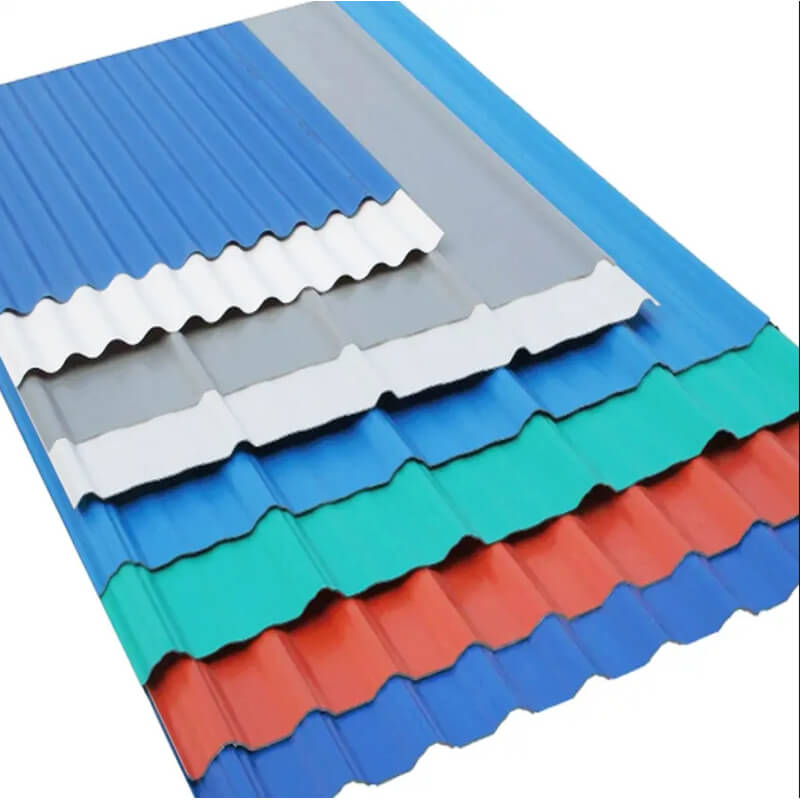

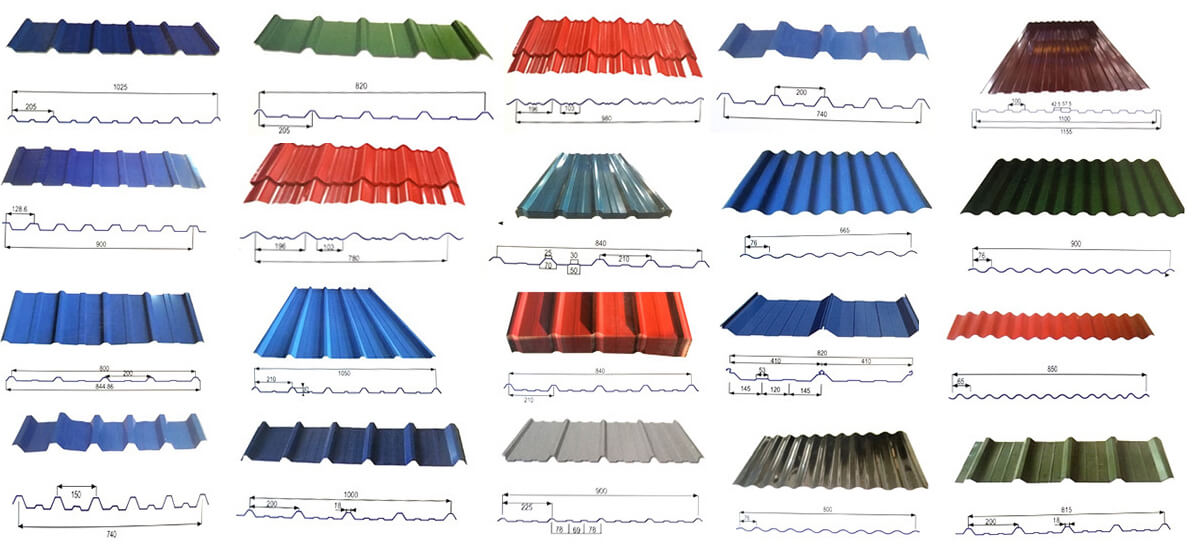

| Design | Wavy, Trapezoidal, Tile, Curved, etc. |

| Colours | As per RAL Color (custom patterns are available) |

| Paintings | PE, SMP, HDP, PVDF |

| Coating Thickness | Top: 11-35 μm Back: 5-14 μm |

| Certificates | ISO 9001, SGS, CE, BV |

| Features | Durable Coating, Corrosion Resistant, Waterproof |

| Package | Standard Export Package |

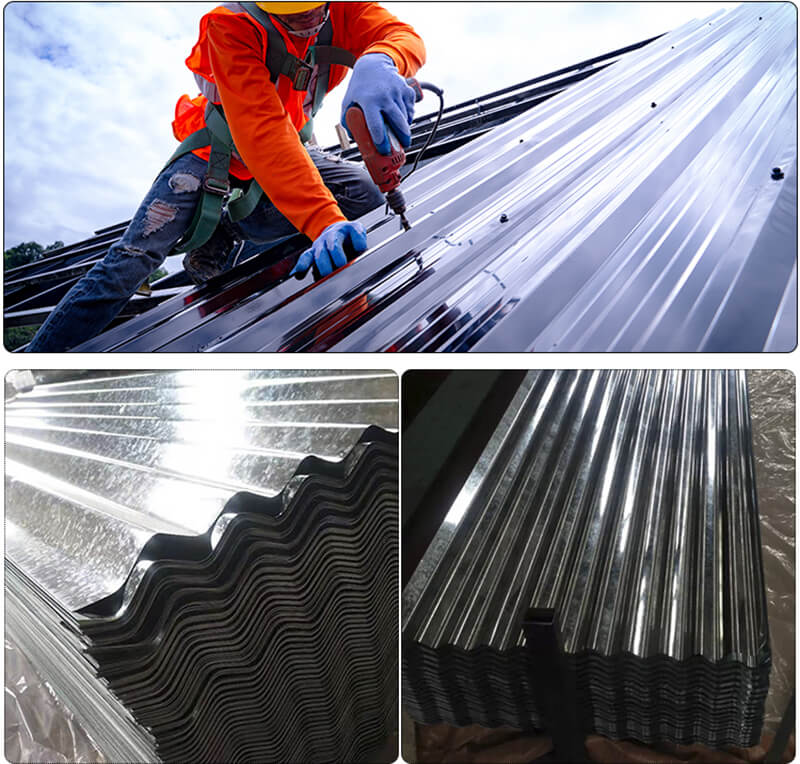

Coated corrugated steel sheets are widely used in the construction industry, such as roofs, wall cladding, windows and doors, ceilings, internal and external decoration, etc. In the past, it was mainly used in industrial and civil buildings, such as warehouses, and garages. While now it is also very popular in large public buildings due to its various designs, such as airport terminals, railway stations, exhibition halls, gyms, theatres, as well as 2008 Olympic Stadium.

With various designs, rich colours, smooth surface, and decorative appearance, color corrugated sheets are suitable for different architectural styles.

- Light in weight (about 10 kg/m2) but high strength (yield strength: 250~550MPa). So it is easy to transport, install, and safe to use. According to data, using coloured corrugated sheets will reduce the construction period by 40%.

- Good heat and corrosion resistance, which can be used for more than 15 years under normal conditions.

- Great formability so that you can use the coated corrugated steel sheets in many areas.

- Environment-friendly building material, which can be recycled.

There are many factors to consider before purchase, such as the substrate, coating, thickness, cost, etc. Below are some tips for your reference.

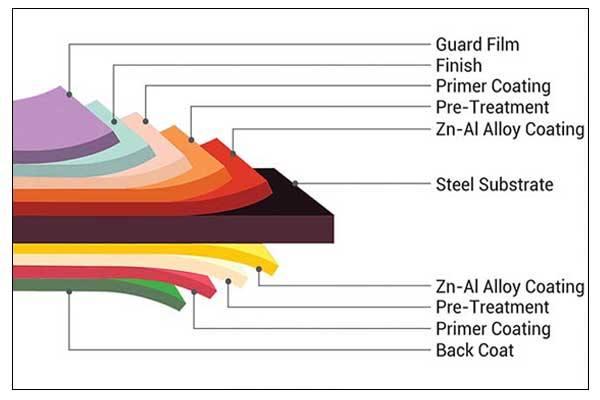

The substrate directly affects the quality of pre-painted corrugated sheets. It is because the painting and profiling process has little impact on the mechanical properties of steel. By comparison, PPGL corrugated sheet is more heat-corrosion resistant, which is more suitable for severe environments. While the affordable PPGI sheet is also durable enough for general applications.

Commonly, the thickness of roof and wall is 0.4-1.6mm, and 0.1-1 mm for ceilings. While if being used as a bearing wall or silo, it should be with a thickness of 2-3 mm or above. Also, there are different designs and wave heights to choose from. But please note that it doesn’t mean the thicker the metal, the better the quality. You should choose upon your needs.

As shown in the table above, our coatings include polyester (PE), silicone modified polyester (SMP), high durability polyester (HDP), and polyvinylidene fluoride (PVDF). The hardness, flexibility, adhesion, and performance of different paints are different. You need to choose the coatings based on their adhesion, use environmental, service life, etc.

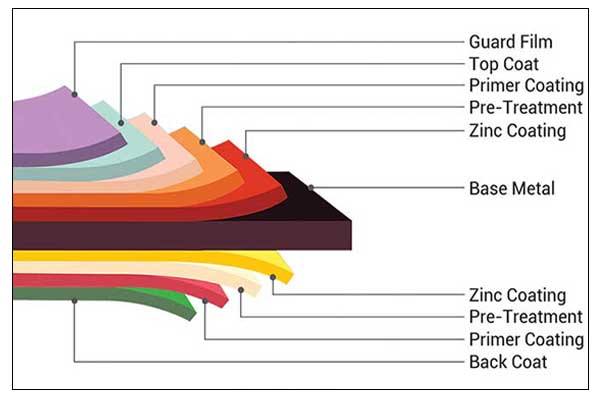

The color coating steel consists of base metal, zinc or Al-Zn coating, pre-treatment coating, primer, and finish coatings (top & back sides), which directly affect its corrosion resistance. So the thickness of coating should be confirmed according to the corrosion of use environment. Commonly, both sides are coated twice. For some special uses, such as home appliances, it may be painted three times. While if the backside is to be bonded, a single layer is recommended.