galvanized steel coil,Stainless steel coil,PPGI steel coil,stainless steel pipe

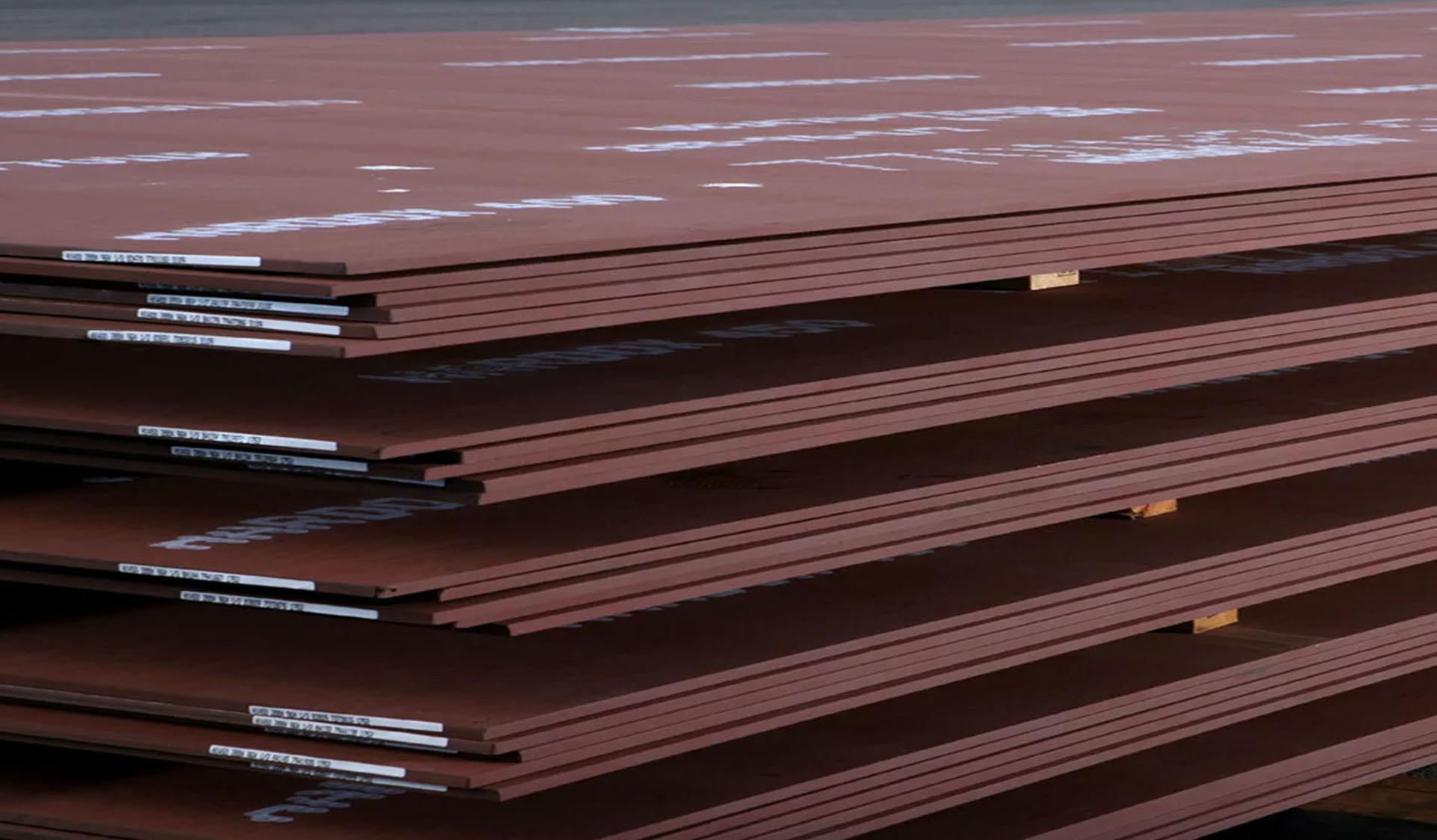

nm 500 wear resistant steel plate

03/26/2022

mn13 wear reristant steel sheet plate

03/26/2022nm 400 500 wear resistant steel plate

Wear-resistant steel plate, also called abrasion-resistant or AR plate, is made from steel billets and comes in many grades. Alloys like carbon, manganese, nickel, chrome and boron are added in different proportions. The grades therefore have different mechanical and chemical properties that will produce different results in an end product.

Carbon plays a key role in making the wear plate steel abrasion- and wear-resistant because it increases the steel’s hardness and toughness. But too much carbon alloy will reduce the steel’s tensile strength, making it brittle and susceptible to cracking.

That’s why good steelmaking processes are vital. You need just the right “recipe” with a balance of alloying, heat treatment and chemistry to achieve the properties you want.

Product Details of Wear resistant steel plate

| Standard Grade | DIN: XAR300,XAR400, XAR450, XAR500, XAR600 SGHC SGH340 SGH400 SGH440 SGH490 SGH540 SSAB:400,450,500,550,600;WELDOX700,WELDOX900,WELDOX960 FIN:RAEX400,RAEX450,RAEX500 JIS: JFE-EH360,JFE-EH400,JFE-EH500 GB: NM360,NM400,M450,NM500,NM550,NM600 |

| Thickness | 3-100mm |

| Width | 1500-3000mm |

| Length | according to customer requirement |

| Surface | according to customer requirement |

| Surface | according to customer requirement |

| Package | Standard export seaworthy package,suit for all kinds of transport,or as required. |

| Application | Widely used in a variety of architectural and engineering structures,such as

1.) metal constructions such as buildings,bridges,ships; 2.) transmission tower, reaction tower; 3.) lifting transportation machinery; 4.) industrial furnace;boilers 5.) container frame, warehouse goods shelves, etc |

| performance | 1. Excellent wear resistance 2. Good impact resistance 3. Good heat resistance 4. Good corrosion resistance 5. The varieties and specifications are complete 6. Convenient machining performance |

Welding process is the use of the most advanced open arc welding welding process, the various effects of this process on the erformance of a very small base , and wear to maximize play. Composite wear plate is ordinary steel (Q235 (A3) or heat-resistant steel (15CrMo, 12Cr! MoV , etc. ) , stainless steel plate formed on the entire volume fraction of more than 50% Cr7C3 carbide based wear layer , which with high wear resistance , impact resistance, deformable and welding performance, like steel , like direct texturing , cutting and drilling and other processing sectors , processed into mining engineering components to meet the wear and put into use . wear-resistant material with many compared wear-resistant composite plate has its irreplaceable notable features.

Industries and uses for wear-resistant steel

Wear-resistant steels are used in applications where abrasion, wear and impact are the main causes of failure, not constant pressure or tension. So, such steels make the ideal choice for using in heavy-duty equipment and attachments in challenging or extreme environments.

Typical uses for wear-resistant steels include:

Typical uses for wear-resistant steels include:

- Earthmoving equipment and attachments

- Construction, demolition and recycling

- Material handling, crushing and conveying

- Mining and quarrying

- Cement and other industrial plants

- Agricultural machinery

Factory Show of Wear resistant steel plate

Recommended Products

- Date

- 10/10/2024

Carbon steel, also known as carbon steel, refers to iron-carbon alloy with carbon content Wc less than 2.11%. Generally, it is used after normalizing or quenching.- Date

- 10/10/2024

Carbon steel, also known as carbon steel, refers to iron-carbon alloy with carbon content Wc less than 2.11%. Generally, it is used after normalizing or quenching.- Date

- 09/26/2024

ASTM A284 Carbon Steel Coils is used as parts requiring higher strength and wear resistance or less elasticity, dynamic load and impact load, such as gears, rims, flat springs, crankshafts, etc., and can also be used as castings.