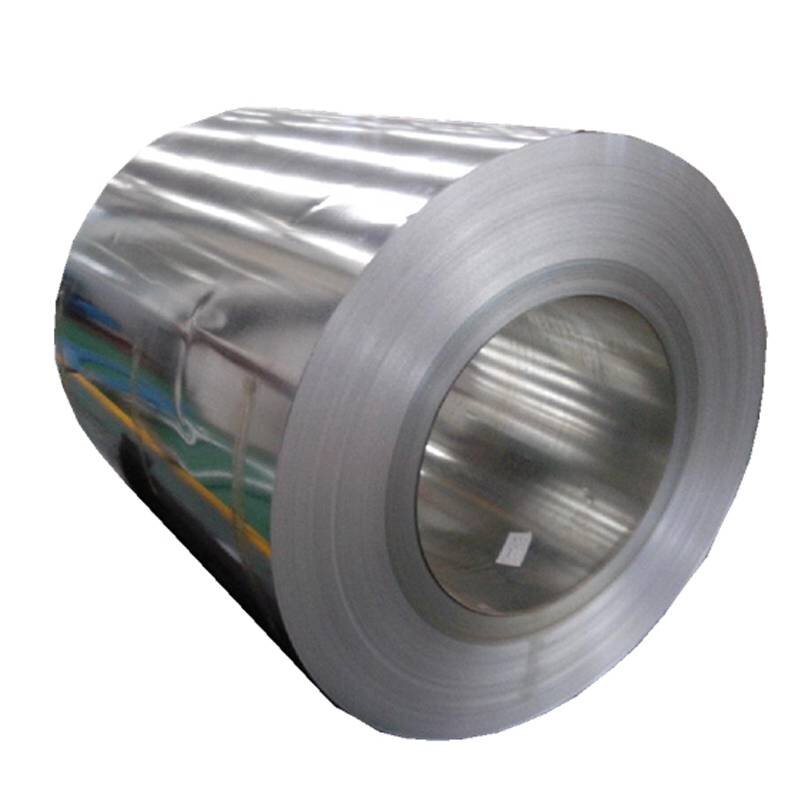

Galvanized Steel Coil

- Galvanized Steel Coil Details

Galvanized steel coil is one of the hot-selling products of Jinhua Steel. It is available in big, regular, small, and zero spangles. Compared to color steel coil, it is more affordable. Also, it has excellent corrosion resistance and durability. That’s why it is extensively used in construction, automobile, furniture, home appliances, etc. Due to its wide applications and good machinability, it is also a great investment project. As a wholesale supplier, Jinhua Steel has its own factory to meet bulk orders timely. Also, we will offer a direct-sale price to lower your cost. If you are interested, please contact us for details!

- Galvanized Steel Coil Specification

Item | Galvanized Steel Coil |

Thickness | 0.2 mm-4 mm |

Width | 600 mm-2,000 mm |

Coil Weight | 3-5 tons (can be customized) |

Surface Structure | Zero spangles, Small spangles, Regular spangles, Big spangles |

Zinc Layer Thickness | 30 g-275 g/㎡ |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Certificates | SGS, BV, ISO 9001 |

Package | Standard Export Package |

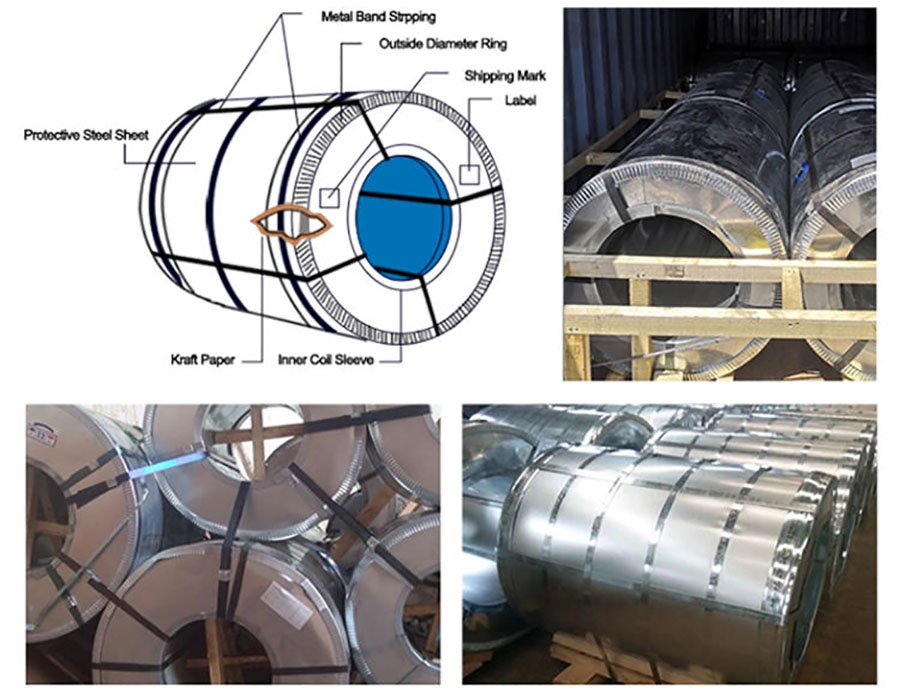

- Package of GI Coil

Steel coils are often packaged with waterproof kraft paper inside and steel sheet outside. Then it will be tied up with steel stripes. In order to fix it during transportation, we will use wood pallets. Below are some pictures for your reference.

- Applications of Galvanized Steel Coil

Galvanized steel coil can be widely used in different applications after further processing, including:

1. Construction

They are often used as roofing, interior and exterior wall panels, the surface sheet of the balcony, ceiling, partitioning walls, windows and doors, gutter, barn, sound insulation wall, etc.2. Home Appliances

GI coil is widely applied to home appliances, such as the base of washing machines, water heaters, refrigerators, microwave ovens, etc.3. Transportation

It is mainly used as decorative panels of cars, decks of trains or ships, containers, road signs, etc.4. Furniture

such as wardrobe, locker, radiator, lampshade, table, bed, bookcase, shelf, etc.5. Other Uses

such as post and telecommunication cable, highway guardrail, billboards, etc.

Why Choose Galvanized Steel Coil?

1. Cost-effective Solution

Compared to GL or color coated steel coils, the galvanized coil is the most cost-effective solution but with similar features, such as great corrosion resistance, good appearance, etc.2. Wide Applications

GI sheet roll is easy to process for different purposes. It is widely used in construction, home appliances, automobile containers, transportation, etc.3. Easy to Transport

Compared to GI steel sheets, coils are easier to transport. In this way, it will save your shipping cost.- Spangles on Galvanized Steel

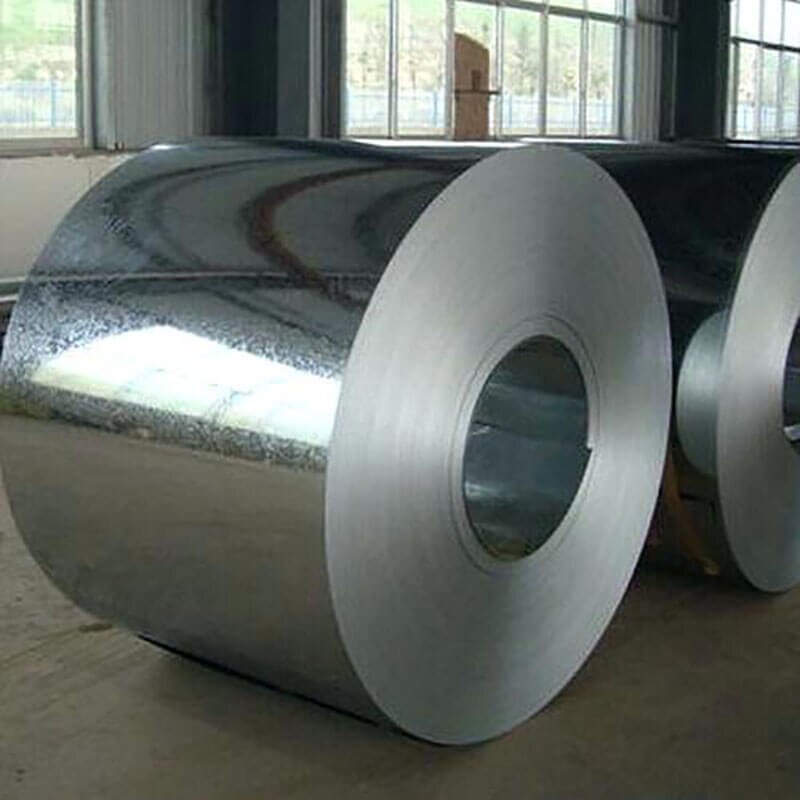

Spangle is formed during the hot-dip galvanizing process. The size, brightness, and surface of spangles mainly depend on the composition of zinc layer and the cooling method. According to the size, it includes small spangles, regular spangles, big spangles, and free spangles. They look different, but the spangles almost will not influence the quality of galvanized steel. You can choose according to your preference and purpose.

- Differences Between Hot-dip and Electro Galvanized Coils

1. Thickness of Zinc Layer

Generally, the thickness of the electro-galvanizing layer is 5~15 μm, and the hot galvanizing layer is often more than 35 μm, or even as high as 300 μm.

2. Resistance to Corrosion

The corrosion resistance of hot-dip galvanized coil is much better than that of an electro-galvanizing one. It is because of the thickness of the zinc layer and the adhesion between the base metal and zinc layer.

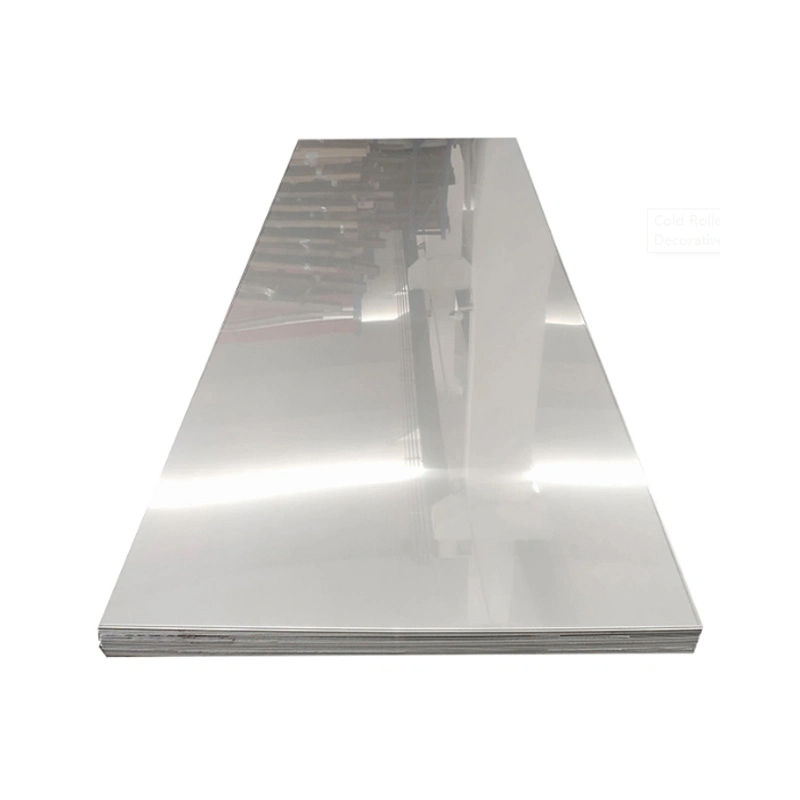

3. Appearance

The appearance of the electro-galvanized coil is more smooth and bright. While the surface of the hot-dip galvanized coil is rough and dull.

4. Applications

Hot-dip galvanizing products are widely used in transportation, building, communication, electric power, energy, automobile, petrochemical, home appliances, and other industries. While the electro-galvanized coil is more suitable for small parts, or indoor environments, etc.

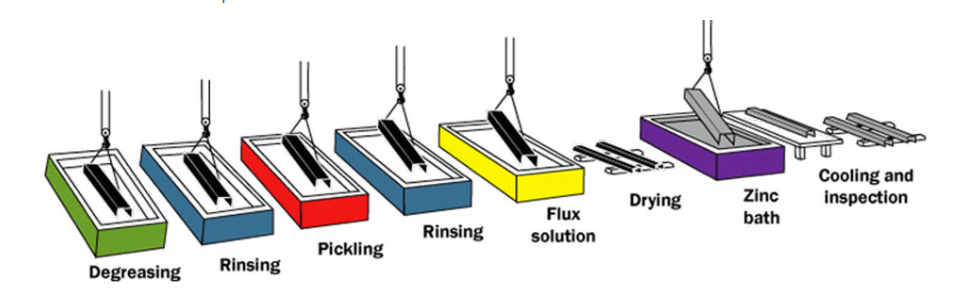

- Hot-dip Galvanized Coil Production Process

- Clean the grease, dirt, and paint on the surface of the steel coil. The coils need to be uncoiled and welded for continuous processing.

- Rinse off the cleaning solution.

- Put into an acidic solution to remove mill scale.

- Wash off the pickling solution.

- Dip the steel into the molten zinc bath and hold for a while to be galvanized.

- Cool down and roll up the steel into coils for sale.

- Our Warehouse

Complete specifications, sufficient supply, standing inventory of more than 100,000 tons, providing stable resources for large-scale projects at home and abroad for a long time, and providing customers with various specifications of import and export business. We have established relationships with major manufacturers, factories and warehouses to provide you with a “one-stop” service.

- Leave Us A Message